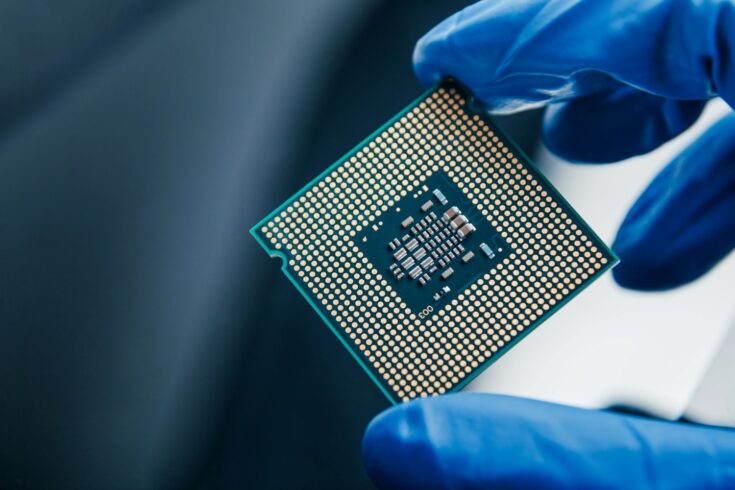

The INTERPOSE-UK project was one of 16 projects funded by Innovate UK to improve and scale-up semiconductor manufacturing and supply chains. The aim of the project was to develop UK capability to produce bespoke interposers, enabling UK companies to capitalise on the heterogeneous integration technologies needed for next generation chip integration. Interposers are functional substrates that enable electrical connectivity between different semiconductor chips in advanced packaging applications.

The partners in the activity are:

- BAE systems (operations) Limited

- Oxford Lasers Limited

- PRP Optoelectronics Limited

- University of Southampton

The consortium’s goal is to mature the bespoke manufacture of glass and silicon-based interposers/redistribution layers and make them commercially available to a wide range of end-user applications beyond consumer products in support of the UK packaging supply chain. The intention is to offer an agile process flow, capable of supporting a variety of applications and markets that the UK electronics systems industry operates in. During the project the consortium demonstrated processes based on 40µm diameter vias on 300µm thick wafers in both glass and silicon and have future plans to scale via geometries further.

BAE Systems – FalconWorks (Filton) was the lead partner for the consortium and undertook the development of via fabrication within silicon interposers as well as leading the interposer design effort with the other partners and undertaking detailed test and characterisation of both glass and silicon interposers.

Oxford Lasers provide high-precision laser processing for the development of advanced features in glass interposers developing new laser processing technologies to fabricate custom through glass vias that will enable advanced 2.5D and 3D heterogeneous integration.

University of Southampton further process the glass and silicon wafers for via fill with electroplated copper and then add front and back side redistribution layer fabrication to complete the interposer formation.

PRP Optoelectronics, who are a manufacturer of integrated MicroLED displays for various civil and military applications, developed demonstration LED systems using the new interposers.

In conjunction with IMAPS-UK (The UK chapter of the International Microelectronics Assembly and Packaging Society), the INTERPOSE-UK partners hosted a workshop to explore the topic of heterogeneous integration of glass and silicon interposers. The event brought together sixty people from across the UK with an interest in advanced packaging and heterogeneous integration.

The consortium will continue to develop UK capability to produce bespoke interposers and work with others in the UK electronic systems and manufacturing ecosystem to help UK companies take advantage of the latest developments in heterogeneous integration and advanced packaging.

John Darlington

John Darlington

Add new comment

To post a comment on this article, please log in to your account. New users can create an account.