It was a pleasure to attend the REACT/TechWorks Semiconductor Industry Workshop at the Royal Society on the 18 September 2025. The event is one of growing number of events that are bringing the semiconductor community together. One of the key aims of this workshop was to improve industry academia collaboration around this very important topic of making the UK electronics industry sustainable.

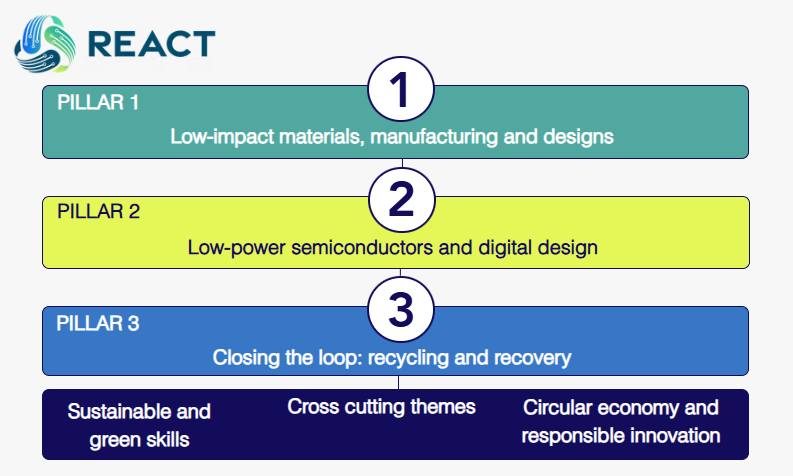

REACT is a unique cross-institution research initiative supporting the electronics industry to become sustainable by transitioning to circular economics and reducing emissions. Despite the positive transformative impact the electronics industry has had on our daily lives, the electronics industry is challenged in many unknown and poorly understood issues that have a negative impact on our planet.

Paul Jarvie, CS Catapult, opened the workshop with an overview of the main REACT themes and the urgent need for environmentally driven design including, energy efficiency during useful life, re-use and life extension of parts and finally recovery of materials at end of life.

Paul highlighted where small improvements are being made in the environmental footprint of electronics such as more efficient power electronic devices but that most benefit comes not from the initial design use of a component part but from extending the life of parts. This is a major issues given the complexity in doing this in existing supply chains all of which are organised to deliver end of first life into very simple waste streams. He talked about how to encourage re-use and the concept of a digital passport for parts. He highlighted the use of precious elements, especially at system boundaries, with the predominant use of gold in connection of semiconductor die and that the current packaging and broader combination into Printed Circuit Boards ("PCB") involves a significant amount of materials to bring an electronic system together.

Jean-Pierre Raskin, UC Louvain, gave the keynote presentation on sustainable manufacturing and circular strategies in electronics. He gave a short history of semiconductor advances and how each decade of advance has lead to the use of more and more of the periodic table of materials and an increase in the number of processing steps needed to manufacture a semiconductor part. Looking at how rare these materials are on our planet and the impact on extracting and using them. While we can extract 330 Kilograms of iron from every tonne of raw ore, only 3g of platinum are produced! All the upstream costs of extracting these materials needs to part of the complete Life Cycle Analysis of semiconductors.

At the other end of life, the recycling of electronics is extremely poor. Of the recycling that is undertaken much is simply shreded for simple metal extraction. The most advanced processor globally can only recover 17 of the 60 elements used in semiconductors. Only, gold, silver, copper and platinum/palladium (4/5 of 17) can be recycled for resale into the market on an commercially viable basis. The industries proliferation of materials used in more advanced transistor nodes is unsustainable when only 4 are economically viable to recycle.

Jean-Pierre went on to look at the demand and therefore impact of electronics. These include, population growth, the increasing uses of electronics in each person's everyday life which when combined with the increasing environmental cost of each semiconductor component gives an increasing growth in the impact of semiconductors over time. He showed that the current trend is for +9% growth in die shipments year on year, +7% increase in semiconductor process steps annually, when these are combined with the ever increasing use of virgin materials, the semiconductor industry is simply not sustainable.

Kiran Crawford, Jaguar Land Rover, is a senior sustainability engineer and gave an interesting presentation from a large systems company perspective. JLR have an ambition to be Net Zero by 2039, this requires decarbonisation of all the materials and components across their value chain. Kiran's focus is on understanding the sustainability impacts of electronics within the car, developing decarbonisation pathways and delivering sustainability improvements into JLR products.

Kiran informed the audience that there are over 5 thousand semiconductor parts in a JLR car! Automotive electronics are the 4th largest environmental impact after the batteries and the body shell materials. The semiconductors parts contribute 30% of the carbon cost, versus the PCB assembly being 60% yet to the semiconductors are becoming a greater percentage of the value of a car. As a car assembler the historic approach to automotive electronics was that each new feature added to a car added a new 'box' adding additional demand on the car's wiring. In the future there is a drive within the automotive sector to consolidate functions and simplify connectivity. There will continue to be an increase in sensors within the car but these need to be a reduction in overall system of system complexity. As extended life is a key to sustainability finding ways to reuse and revalidate automotive electronics in extended vehicle life cycles is an interesting opportunity.

Lenny Koh, University of Sheffield, will be involved in the CHIMES Innovation and Knowledge Centre ("IKC"), outlined the need for more complete Life Cycle Analysis to get a clear understanding of the impact of a product over it’s entire life from extraction of raw materials through manufacture and entire life use to recovery and re-entering the cycle.

She outlined the global nature of semiconductor supply chains and how hard it is to get information on the impact generated by the different parts of the supply chain across the world. She discussed what application areas she felt the UK can be successful in and the potential for new forms of packaging and design for test might help future re-use of semiconductor parts. Her clear message was that to better understand the impact and improve the sustainability of the electronics industry we need to come to together and collaborate. Lenny help define the current landscape and future roadmaps as part of the new CHIMES IKC.

Robert Nicol, ST Microelectronics, gave an overview of the broad area of semiconductor parts produced by the company. He also presented their efforts to reduce their impact as a manufacturer of semiconductors. Like the earlier presenters there is growing demand in electronics from new sensors, more performance for applications such as AI, immersive environments that will increase our use of electronic devices in our daily lives. Whether it is consumer pull for novel functions or companies encouraging consumption of new devices more frequently, there is an ever growing demand for semiconductor part shipments that have reached over 1.4 Billion per year.

Some parts in fast moving consumer markets like mobile phones have shorter lifetimes that say automotive with a minimum 10 year life and 10 years of additional part supply and support. Improving reliability and extending life are interesting opportunities but part certification is a key concern, especially in second use. How can we be sure of the lifetime of the part. Much more understanding of the holistic life of a part from raw material provision through to end of life is needed.

As a semiconductor part supplier we have limited insight and once parts are packaged and distributed to system manufacturers there is limited visibility of what happens. Many simply waste streams have resulted in most land fill sites being highly contaminated with materials including dangerous elements such as cadmium.

Steve Riches, IMAPS UK, gave a presentation on a recent UKRI funded collaboration project on the breakdown and recycling of a power module and how there are actions that can be taken to improve the manufacture of such models to improve our chances of second use and recycling of materials.

There were also presentations from the UK Innovation and Knowledge Centre's, in photonic systems (CORNERSTONE), wide bandgap and power semiconductors (REWIRE) and Heterogenous Integration and advanced packaging (CHIMES).

The new IKC in Heterogenous Integration, can play a key role in reducing the impact of the electronics industry. That could be in driving a change in materials use, re-use and recovery and recycling. It could be in reducing the amount of manufacturing process and the inverse the disassembly effort of electronic system offerings. All of these will require more informed and better design decisions at all stages of product conceptualisation through use and re-use to end of life.

The fundamental observation from the workshop though was the simple fact that our demand for new semiconductor parts is outweighing all our efforts to make the electronics industry more sustainable. The economic balance and our value propositions are highly loaded towards growing consumption and virgin use and more needs to be done to change business models and economic drivers, these are issues for the IKC's Coordination work area which aims to understand the 'landscape' in which HI can have an impact. These economic issues are in addition to the IKC's role in driving significant technological change by better design and product engineering under the IKC's Core Design work area and in the Proof of Concepts developed with UK industry as part of the co-created projects work area. Finally the IKC's Research work area is looking forward to collaborating closely with REACT on this very important topic of making the UK electronics industry sustainable.

John Darlington

John Darlington

Add new comment

To post a comment on this article, please log in to your account. New users can create an account.